Role of Robotics in Modern Industry

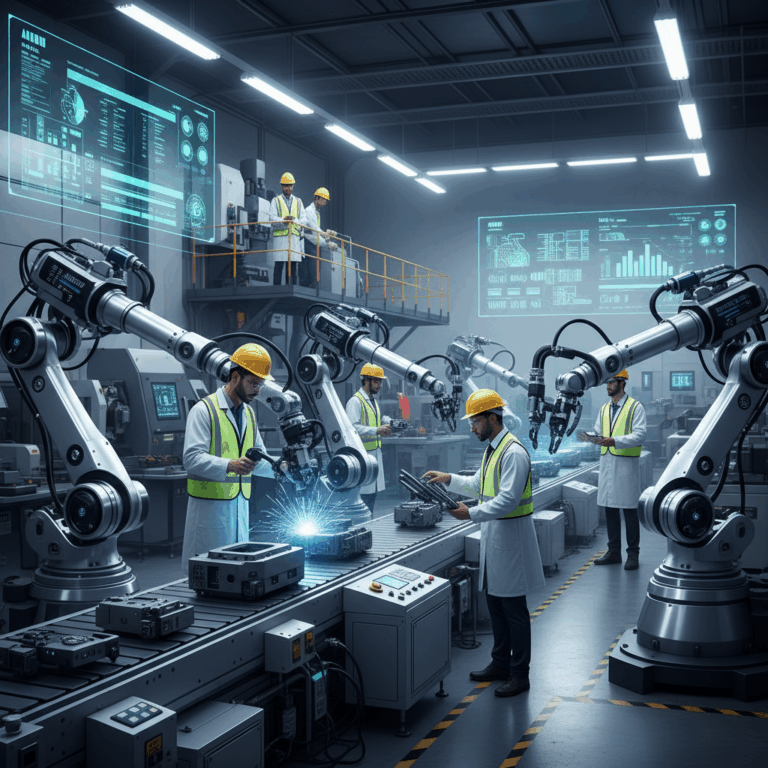

Robotics plays a crucial role in modern industry by driving efficiency and precision in production processes. These systems revolutionize how factories operate worldwide.

With advancements in automation, robots now execute complex tasks, reducing human error and increasing operational speed. This leads to improved product quality and consistency across industries.

Robots are transforming multiple sectors by enabling innovations that enhance manufacturing, logistics, and overall supply chain management with significant impact.

Enhancing Efficiency and Precision

Industrial robots improve efficiency by automating repetitive tasks, allowing faster production cycles without sacrificing quality. Their precision outperforms human capabilities through advanced control systems.

Equipped with intelligent sensors and algorithms, robots maintain consistency in assembly, welding, and painting, which minimizes defects and waste in manufacturing processes.

This level of precision also enables handling delicate components, ensuring superior product standards while optimizing resource use and lowering operational costs.

Applications Across Sectors

Robots are widely used across industries like automotive, electronics, pharmaceuticals, and logistics, adapting to specific workflow requirements and environmental conditions.

In logistics, autonomous mobile robots navigate warehouses independently, streamlining inventory management and order fulfillment with high flexibility and reliability.

Specialized robots excel in niche sectors such as cleanroom environments for semiconductor production and surgical assistance in healthcare, improving outcomes and efficiency.

Advanced Capabilities of Industrial Robots

Industrial robots today are enhanced by cutting-edge technologies like artificial intelligence and machine learning. These technologies enable robots to perform complex tasks with greater autonomy and adaptability.

The integration of intelligent systems transforms robots from simple automatons into responsive machines that can learn, optimize operations, and work safely alongside humans in dynamic environments.

Moreover, specialized robots and autonomous mobile robots are expanding robotics applications across manufacturing and logistics, driving efficiency and innovation at an unprecedented scale.

Artificial Intelligence and Machine Learning Integration

Incorporating artificial intelligence (AI) allows industrial robots to interpret data, recognize patterns, and make decisions independently. This boosts their ability to handle varying tasks without human intervention.

Machine learning further empowers robots by enabling continuous improvement. Robots can adapt to new scenarios by learning from previous experiences, optimizing processes, and reducing downtime.

The dynamic nature of AI-enhanced robots improves quality control, as they detect defects and adjust operations in real-time, ensuring superior manufacturing standards.

Impact on Industry

AI and machine learning enable predictive maintenance, allowing robots to foresee component failures and schedule timely repairs, significantly minimizing unexpected stoppages.

Autonomous Mobile Robots in Logistics

Autonomous mobile robots (AMRs) are revolutionizing logistics by independently navigating complex environments such as warehouses and factories, increasing throughput and reducing labor costs.

Equipped with advanced sensors and navigation systems, AMRs excel in transporting goods, managing inventory, and optimizing pathways without human guidance or fixed tracks.

Their flexibility supports rapid reconfiguration of supply chains, especially valuable in dynamic settings like e-commerce fulfillment centers.

Specialized Robots for Niche Applications

Specialized robots address unique industry demands, such as cleanroom robots that ensure contamination-free environments critical in semiconductor manufacturing.

In fields like pharmaceuticals and electronics, robotic arms with vision systems perform high-precision assembly and quality inspection, enhancing reliability and accuracy.

Healthcare also benefits from these robots, where robotic manipulators assist in delicate surgeries and automate laboratory tasks, advancing patient care and operational efficiency.

Benefits of Industrial Robotics

Industrial robotics offers significant benefits including enhanced safety and productivity, crucial for modern manufacturing environments. Their adoption transforms workplace dynamics.

By automating hazardous tasks, robots protect workers from injury. They also maintain high output levels reliably, contributing to more efficient and safer factory operations.

The integration of robotics brings not only operational improvements but also increased data availability that supports smarter decision-making and predictive maintenance strategies.

Improving Safety and Productivity

Robots take on dangerous tasks such as handling toxic materials or working in extreme conditions, thus dramatically reducing workplace injuries and accidents.

Continuous operation without fatigue allows robots to sustain higher productivity levels than human workers, increasing output while lowering labor costs.

Automation also minimizes human error, leading to consistent quality in production processes, which directly improves overall efficiency and product reliability.

Data-Driven Decision Making and Maintenance

Industrial robots collect real-time operational data that enables companies to optimize workflows and improve resource allocation through informed decisions.

Data analytics supports predictive maintenance by identifying potential equipment failures before they occur, reducing downtime and costly repairs.

This proactive approach enhances machinery lifespan and ensures smoother production cycles, contributing to smarter and more resilient manufacturing systems.

Future Trends in Robotics and Automation

The future of robotics in industry centers on greater collaboration between humans and robots, and enhanced adaptability. These trends promise smarter, more efficient production systems.

Industries are increasingly adopting robots capable of learning and adjusting to new tasks dynamically, creating flexible manufacturing environments that can respond to evolving demands.

Additionally, sustainable manufacturing practices powered by robotics are driving the industry toward reducing waste and energy consumption, aligning with global environmental goals.

Collaboration and Adaptability of Robots

Robots are evolving into collaborative partners, designed to work safely alongside humans without barriers. This enhances teamwork and increases overall productivity.

Adaptability enables robots to handle a wider variety of tasks and quickly switch between operations, making manufacturing more flexible and responsive to changes.

Advanced sensors and AI facilitate real-time learning, allowing robots to adjust to new environments and unexpected situations, which reduces downtime and improves performance.

Impact on Sustainable Manufacturing

Robotics is pivotal in advancing sustainable manufacturing by optimizing resource usage, reducing waste, and minimizing emissions during production processes.

Automated systems allow precise control over materials and energy, supporting cleaner manufacturing and helping industries meet strict environmental regulations efficiently.

Energy Efficiency and Waste Reduction

Robots optimize production steps to limit excess materials and energy usage, lowering the carbon footprint of factories and fostering greener operations.

Predictive maintenance, driven by robotic data analytics, prolongs equipment life and reduces resource consumption by preventing unexpected breakdowns.