Definition and Core Concepts of Digital Simulations

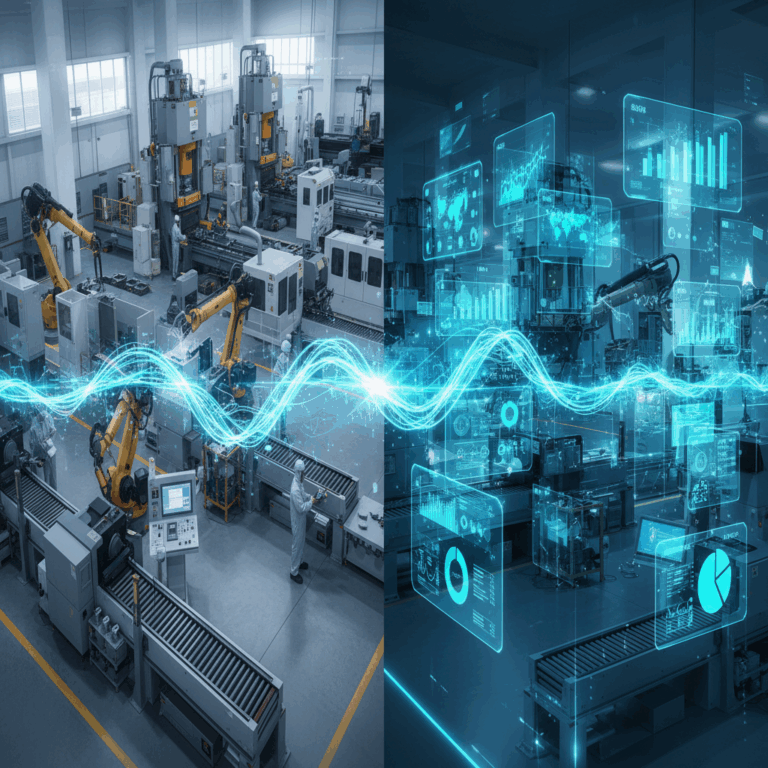

Digital simulations are virtual replicas of real-world physical objects, systems, or processes. They enable detailed analysis, testing, and optimization in a controlled digital setting.

By mimicking actual behaviors, simulations provide a platform for experimentation without impacting real operations. This fosters safer, more efficient decision-making in various industries.

What Are Digital Simulations?

Digital simulations create dynamic, virtual models that represent physical entities or processes. These simulations integrate sensor data to reflect real-time conditions accurately.

They help businesses visualize system behavior under different scenarios, supporting validation and problem-solving before deploying changes in real environments.

Advanced simulations use mathematical algorithms and physics-based models to ensure realistic and precise representation of complex systems.

Role of Digital Simulations in Digital Twin Technology

Digital simulations form a foundational part of digital twin technology by allowing continuous and real-time virtual modeling of assets. This integration drives accurate performance prediction.

They enable early detection of potential failures and operational issues by constantly comparing simulation outputs with live data, helping industries improve maintenance and efficiency.

Simulations also enhance lifecycle management, providing critical insights from installation through to decommissioning, thus supporting proactive strategic planning.

Industrial Applications of Digital Simulations

Digital simulations are pivotal in transforming industrial sectors by enabling virtual modeling of complex processes and systems. This technology supports optimization, predictive analysis, and informed decision-making.

Across industries, simulations reduce risks and costs while improving productivity by allowing stakeholders to test scenarios and foresee potential issues before they impact actual operations.

Manufacturing Process Optimization and Predictive Maintenance

In manufacturing, digital simulations optimize production workflows by replicating entire processes in a virtual setting. This helps identify bottlenecks and enhance equipment efficiency.

Simulations leverage sensor data to predict when machinery might fail, enabling predictive maintenance. This proactive approach minimizes downtime and reduces expensive repairs.

By testing product variations digitally, manufacturers can refine designs rapidly, customize outputs, and accelerate time-to-market, all while maintaining high quality standards.

Applications in Energy and Automotive Sectors

Energy companies employ digital simulations to optimize asset performance, such as managing wind farm efficiency or refining operations in processing plants, improving sustainability and output.

Automotive manufacturers use simulations to assess vehicle component durability and safety, supporting maintenance scheduling and enhancing overall reliability with less physical testing.

This approach aids in reducing costs and development times while providing detailed insights for innovation in both sectors.

Construction and Healthcare Industry Use Cases

In construction, simulations assist with project planning by integrating environmental conditions and infrastructure data, improving project timelines and reducing risks.

Healthcare uses digital twins to model hospital operations or patient-specific organ behavior, allowing virtual testing of treatments and improving patient outcomes.

These applications highlight how digital simulations foster safer, smarter environments and resource-efficient management in critical fields.

Benefits of Digital Simulations in Industry

Digital simulations significantly enhance operational efficiency by enabling precise monitoring and control of industrial processes. They reduce downtime and improve asset utilization.

By allowing risk-free testing and scenario analysis, simulations help companies identify potential issues early, minimizing costly errors and improving safety standards across operations.

Improving Operational Efficiency and Risk Reduction

Digital simulations optimize operations by enabling real-time monitoring and predictive analytics. This leads to faster decision-making and more efficient resource allocation in industries.

Early detection of failures through simulation reduces unplanned downtime, lowering maintenance expenses and preventing safety incidents, thus protecting workers and equipment.

These benefits contribute to streamlined workflows, higher productivity, and enhanced reliability of assets, ultimately driving competitive advantage in industrial markets.

Supporting Innovation and Resource Optimization

Simulations foster innovation by allowing companies to experiment with new designs, processes, and configurations virtually, accelerating product development cycles.

They help optimize resource usage by simulating different operational conditions, enabling organizations to reduce waste, save energy, and improve sustainability practices.

By integrating simulation data with digital twin platforms, industries can continuously refine their strategies, improving both efficiency and environmental impact over time.

Integration and Lifecycle Management

Effective integration of digital simulations with real-time data is essential for continuous monitoring, enabling industries to respond swiftly to evolving conditions. This continuous flow of information supports proactive decision-making.

By combining simulations with live sensor input, companies gain a comprehensive understanding of asset performance, allowing dynamic adjustments that optimize operations and extend equipment life.

Continuous Monitoring and Real-Time Data Use

Continuous monitoring relies on the constant input of real-time data into digital simulations, creating a live reflection of physical systems. This enables instant detection of anomalies or deviations from expected performance.

Real-time data enhances decision-making by providing current system status, facilitating predictive maintenance, and reducing downtime through early fault identification and rapid response.

Integrating digital simulations with real-time data also supports adaptive control strategies, where systems self-adjust based on simulated forecasts and present conditions, improving efficiency.

Lifecycle Management from Installation to Decommissioning

Digital simulations assist in managing assets throughout their entire lifecycle, from installation to decommissioning, by offering insights that improve planning, operation, and end-of-life handling.

This comprehensive management approach helps optimize resource use, reduce operational risks, and inform timely upgrades or replacements to extend asset viability.

Strategic Insights through Virtual Lifecycle Modeling

Through virtual lifecycle modeling, organizations can simulate scenarios for maintenance scheduling, capacity expansions, or environmental impact, ensuring sustainable and cost-effective management.

This foresight supports long-term strategic decisions, enhances asset value, and aligns operational goals with broader industry standards and compliance requirements.